The complete line for ball manufacturing

Quality results, innovation, and productivity optimization

The advantages of the complete line

The line ensures flexibility and continuous innovation. With the concatenation of machinery, competitiveness increases: balls of different types can be produced without wasting material, while maintaining high quality standards.

Highest product quality

Quality begins in the first production phase. The line ensures precision from the sheet to the ball.

Innovation

Cutting-edge technologies and new accessories enable the production of lighter, more competitive balls.

Production optimization

The complete line boosts productivity by reducing material waste and streamlining workflows.

Flexibility

With TVN Tech molds, it's possible to produce any type of ball without modifying the machinery.

The 7 phases of ball manufacturing

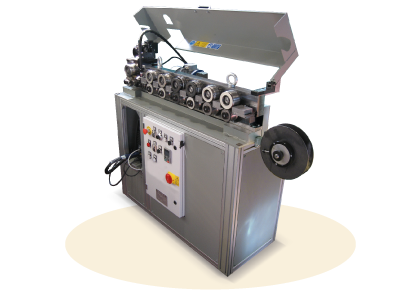

Multiple strip cutter machines

Ensures cutting accuracy within hundredths of a millimeter, with complete repeatability.

Tube forming machine

Manufactures perfectly welded tubes of various profiles and sizes, offering utmost reliability for continuous operation.

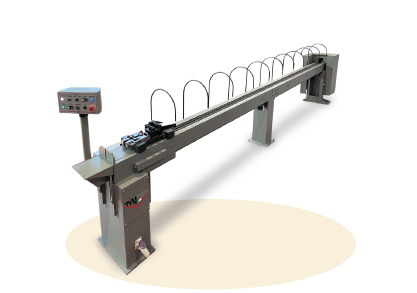

Chain wire-drawing machine

The length of the machine and working stroke are customizable, speed is adjustable. Maintenance is reduced to simple level controls.

Ball machine

Continuously produces loose balls, ball chains, elastic chains or rosary chains. The mechanical tube feed with a cam system ensures the highest productivity.

Rolling ball machine

The work cycle is customizable and saveable, with fully automatic control. Its solid structure guarantees easy maintenance.

The advantages of TVN Tech lines

Advanced technology

The line is available in Industry 4.0 Ready versions: machines are interconnected to automate processes and improve efficiency.

Custom layout

We create 100% custom projects to optimize space and achieve the desired productivity level.

Spare parts

We guarantee fast assistance thanks to a well-stocked warehouse of equipment, accessories, and spare parts.

Machine reliability

Each model is built according to “CE” standards with first choice components

The complete support by TVN Tech

Consulting

We offer a personalized approach and strategic support, guiding our clients in choosing the solutions best suited to their production needs.

In-house production

TVN Tech machinery is designed and manufactured internally, starting from a thorough research process and the selection of the most durable and high-performance materials.

Installation

We make sure everything is ready for the machine startup. Our team of experts oversees the installation to guarantee a smooth implementation.

Training

Through a dedicated training service, we provide our clients with all the necessary skills to make the most of each machine.

Industry 4.0 ready versions!

Fill out the contact form

FOR MORE INFORMATION

If you want more information about the product fill out the form