The complete line for heavy tube manufacturing

Flexibility in processing and zero waste of precious metal

The advantages of the complete line

The line represents a strategic choice for optimizing investment: thanks to state-of-the-art machinery, it is possible to produce tubes of various types and sizes with no material waste.

Minimal waste from the beginning of production

The tube sharpener inserts the tube directly into the hydraulic wire-drawing machine, significantly reducing material waste.

Processing flexibility

The complete line allows for the production of light or heavy tubes, including solid ones, with variable thicknesses and diverse lengths, including extra-long sizes.

Structural stability

Each model is built according to “CE” standards using first choice components to ensure maximum structural durability.

The 3 phases of tube manufacturing

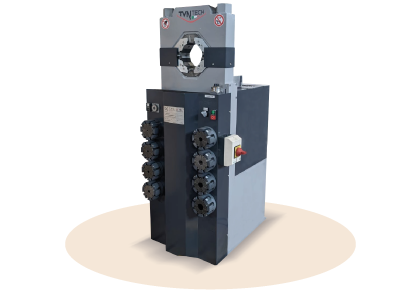

Tube sharpener

It guarantees minimum metal waste, high-quality results thanks to the reduced size of the tips, and remarkable versatility due to the range of clamps available in different diameters.

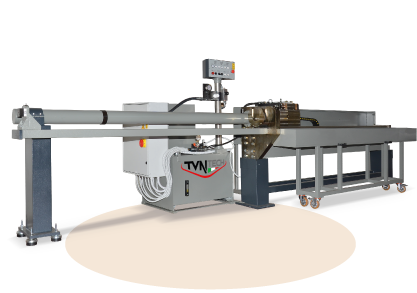

Hydraulic wire-drawing machine

Suitable for the production of wedding rings, rings and bracelets, it produces perfectly straight tubes, ready for CNC processing, with the highest precision and minimum metal waste.

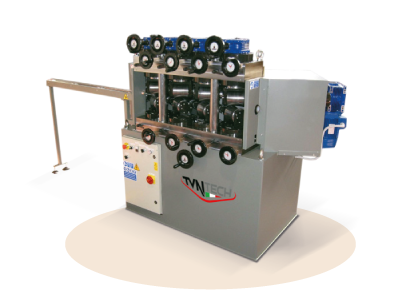

Tube straightening machine

It straightens tubes in gold, silver and their alloys with a final tolerance of 0.3/0.5 mm per meter. The entry guide plate and the exit counter-bench ensure precision and complete repeatability.

The advantages of TVN Tech lines

Advanced technology

The line is available in Industry 4.0 Ready versions: machines are interconnected to automate processes and improve efficiency.

Custom layout

We create 100% custom projects to optimize space and achieve the desired productivity level.

Spare parts

We guarantee fast assistance thanks to a well-stocked warehouse of equipment, accessories, and spare parts.

Machine reliability

Each model is built according to “CE” standards with first choice components

The complete support by TVN Tech

Consulting

We offer a personalized approach and strategic support, guiding our clients in choosing the solutions best suited to their production needs.

In-house production

TVN Tech machinery is designed and manufactured internally, starting from a thorough research process and the selection of the most durable and high-performance materials.

Installation

We make sure everything is ready for the machine startup. Our team of experts oversees the installation to guarantee a smooth implementation.

Training

Through a dedicated training service, we provide our clients with all the necessary skills to make the most of each machine.

Industry 4.0 ready versions!

Fill out the contact form

FOR MORE INFORMATION

If you want more information about the product fill out the form