The complete line for ash treatment

Homogeneity and certainty of results in precious metal recovery

The advantages of the complete line

The line is designed to ensure high-quality results and consistent reliability in precious metal recovery. With state-of-the-art technology and carefully selected materials, it is a secure investment as it optimizes the recovery process and reduces waste.

Homogeneity of results

The powder mixer ensures a perfectly homogeneous batch, minimizing waste and product variation.

Consistent quality

The line guarantees maximum correspondence between the initial ash sample and the result of processing.

Maximum durability

Each model is designed and built in-house according to CE standards with first choice components.

Maintenance without machine change

TVN Tech machines are designed to return to 100% of their capabilities with ordinary and extraordinary maintenance.

The 5 phases of ash treatment

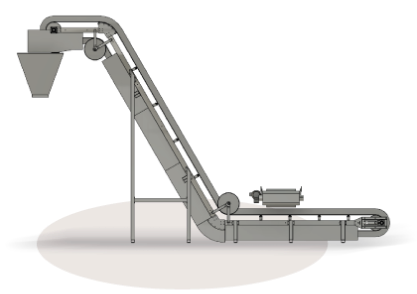

Conveyor belt

It optimizes processing times and increases productivity by automating the entire line.

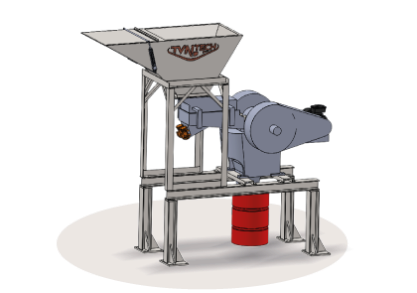

Jaw mill

To pre-mill crucibles, borax, and recovery material after incineration and speed up the subsequent pulverization.

Grinding mill

With a rotor in special double-armored steel, moved by a motor with hydraulic joint and transmission with gears in an oil bath.

Automatic conveyor system

A state-of-the-art system for the automatic transportation of raw materials, fully customizable.

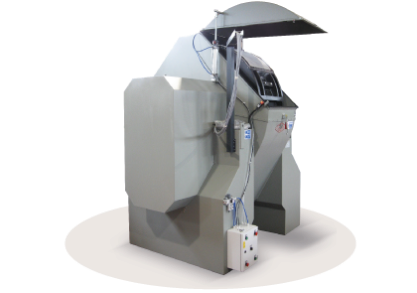

Mixer

The transmission in oil bath gears and the coupling of the motor with the hydraulic coupling provide great reliability and excellent mixing performance.

The advantages of TVN Tech lines

Advanced technology

The line is available in Industry 4.0 Ready versions: machines are interconnected to automate processes and improve efficiency.

Custom layout

We create 100% custom projects to optimize space and achieve the desired productivity level.

Spare parts

We guarantee fast assistance thanks to a well-stocked warehouse of equipment, accessories, and spare parts.

Machine reliability

Each model is built according to “CE” standards with first choice components

The complete support by TVN Tech

Consulting

We offer a personalized approach and strategic support, guiding our clients in choosing the solutions best suited to their production needs.

In-house production

TVN Tech machinery is designed and manufactured internally, starting from a thorough research process and the selection of the most durable and high-performance materials.

Installation

We make sure everything is ready for the machine startup. Our team of experts oversees the installation to guarantee a smooth implementation.

Training

Through a dedicated training service, we provide our clients with all the necessary skills to make the most of each machine.

Industry 4.0 ready versions!

Fill out the contact form

FOR MORE INFORMATION

If you want more information about the product fill out the form